A wise human would have an understanding of the supply chain and how the pieces fit together. But it’s against our nature to think about it.

Paolo Bacigalupi

It’s common to find topics around supply chain optimization on the agenda of board meetings – in fact, over 85% of senior executives say that refining supply chain performance is one of their top priorities.

Why is that?

It’s simple. A lean sustainable supply chain process is crucial to maintaining profit and happy and loyal customers.

Moreover, in the last several years, beginning with the Trump Tariffs on Chinese supply sources and compounded by the pandemic, we have seen significant supply chain disruption.

Supply chain excellence has come to mean more than supply chain efficiency. The new Supply chain strategy now requires supply chain transformation to include supply chain resilience.

So, all supply chain leaders have a shared responsibility in building sustainable supply chains for their businesses.

If you’re new to the business’s planning and logistics side or simply want to understand this process better, I wrote this quick guide to help you get a handle on basic best practices for supply chain management (SCM).

- What are Supply Chain and Supply Chain Management?

- What are Strategic Supply Chain Priorities?

- What are the major Trends affecting the Supply Chain?

- Conclusion

- Frequently Asked Questions

- What is a supply chain?

- What is Supply Chain Management?

- What is the difference between supply chain and logistics?

- What is the difference between supply chain and operations?

- What is Supply Chain Resilience?

- What Is a Sustainable Supply Chain?

- What Is Sustainable Supply Chain Management?

- What is a digital supply chain?

- Helpful Materials

What are Supply Chain and Supply Chain Management?

Supply chains are also called a ‘value chain’ or ‘demand chain.’ While each supply chain is unique, we generally define this chain as a set of processes involved in producing and distributing a product or service.

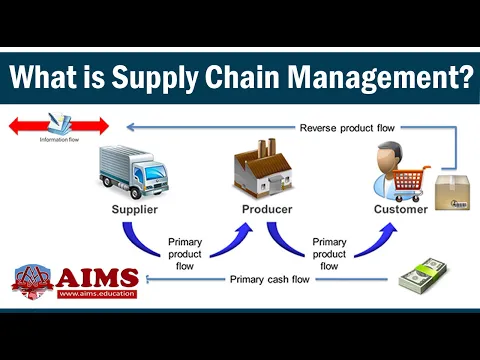

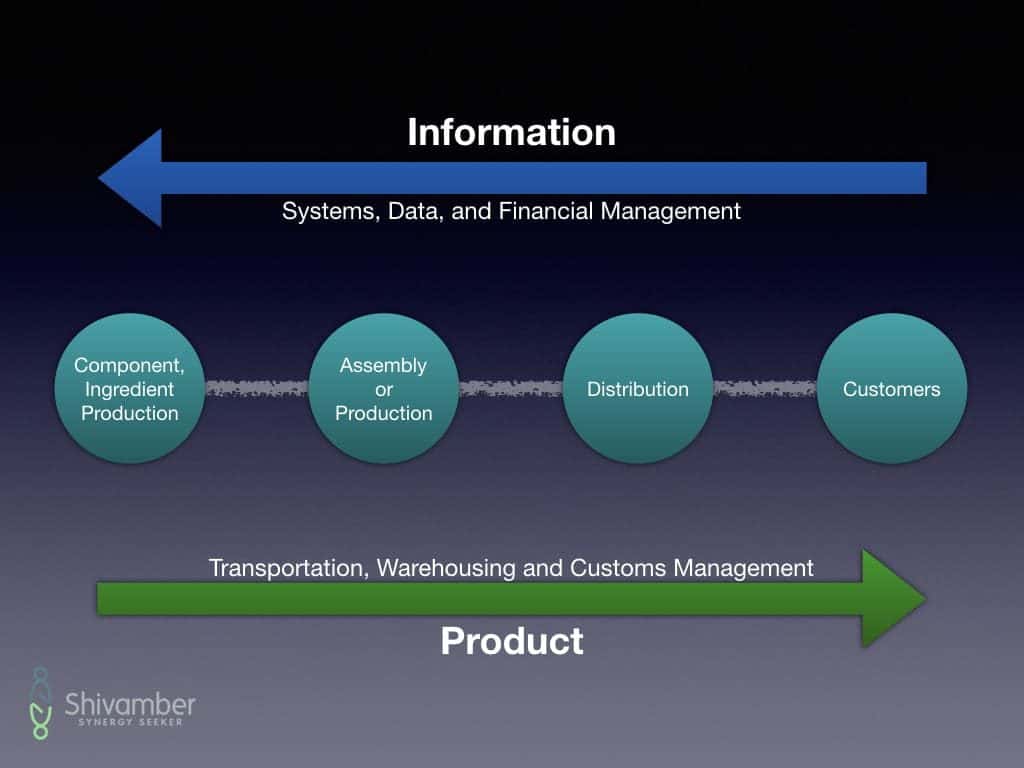

It encompasses a two-way network of participating companies that add or create value along the way, from component/ingredient procurement to the delivery of a finished product or service to an end-user.

It covers a variety of activities such as product development, manufacturing, logistics, and even after-sales service and the information systems required to manage these activities.

Participants in the supply chain are linked by the flow of information from end-users back to suppliers. The information flow also drives a corresponding movement of physical materials from suppliers to end-users.

While the physical flow is visible to the outside world and involves the conversion, storage, and movement of materials, the information flow is virtual, carrying all the data required between chain participants to allow long and short-term coordination.

Example – A Potato Chip Supply Chain

The potato chip supply chain begins with customer expectations and product design. For example, if the product is consumed in bulk, such as in a restaurant or party, that will be a different product expectation than if an individual will consume the product as a snack. Therefore, one design will require bulk products, while the other will require individual size packages.

A significant element that might impact the ultimate cost of the potato chip might be the amount of skin that has to be peeled and thrown out.

To reduce the peeling losses, one manufacturer might choose to deliver potato chips with the skin attached. For that chip company, they will need a potato with edible skins. But if consumers prefer chips without skins, then those chip suppliers will want potatoes with thinner skins that human or automated peelers can remove easily in the manufacturing process.

The supply chain solution they will design will start with the seeds used to plant a specific type of potato, which chip producers can use more easily in the manufacturing process. One major chip manufacturer famously engineered a potato with a fragile skin layer. The potatoes would effectively lose their skin as the potato rolled from the truck onto a conveyor belt into the chip factory.

The complete potato chip supply chain would include the planting, harvesting, and delivering potatoes from farms to the chip factories. All the raw materials, such as potatoes, spices, cooking oils, and packaging, will be combined to create the finished product at the chip factory. The factories would process the potato, skin, split, slice, cook, and ultimately fill distributable packages with chips. Finally, the finished goods would be stacked into delivery boxes sent to storage and retail locations where the ultimate consumer can purchase them.

The diagram below depicts flows to various areas of participation in a typical supply chain.

The term “supply chain management” then refers to the active management of supply chain-related activities to increase long-term competitive advantage and customer value at the same time.

In general, the performance of your supply chain will be determined by how you integrate your supply chain based on your choices in three equally important elements and then how you tactically manage it in a disciplined manner to deliver the desired performance.

What are Strategic Supply Chain Priorities?

It would be best if you were concerned about the following strategic supply chain elements:

- Customer Expectations (today and in the future)

- Supply Chain Structure

- Eco-system of Partnerships

Even the most experienced supply chain manager finds it challenging to manage the above components creatively and sustainably.

However, when navigated correctly, the decisions you make can unlock significant performance improvements in your supply chain, so it’s well worth the effort to comprehend.

Let’s take a closer look at why these components are so important.

Supply Chain Priority 1 – To Meet or exceed your Customer Expectations

The modern customer’s increasingly demanding nature necessitates a lean, disciplined supply chain.

When you have ‘fatty bits’ attempting to meet customers’ demands with high expectations, you usually have an expensive supply chain or one that is simply underperforming.

You may hear creatives discuss ‘brand strength’ – it’s a hot topic that marketers measure after launching various social media campaigns, TV commercials, and viral videos. Brand strength, customer experience, and relative customer expectations, on the other hand, are influenced not only by external marketing efforts but also by supply chain performance in terms of the three variables that customers care about the most: time, quality, and value.

Let’s take a quick look at these significant areas of concern:

You must Deliver Value

The simplest definition of value is “benefits minus costs.”

Customers prefer products that are the most valuable to them, i.e., provide the most benefits for the cost they will incur. As a result, external factors such as competition, which drive price/benefit comparisons, will more likely shape your customer expectations.

As a significant contributor to costs, the supply chain will directly impact the price and value of the resulting service or product.

You must Ensure Quality

The supply chain has a direct impact on the quality of a product or service.

Traditionally, quality meant ‘how well a product worked.’ Still, the modern consumer’s definition of quality has been redefined to include more service-related elements like flexibility, customization, and so on, all of which can be influenced by the supply chain.

You must Focus on Speed to Deliver on Time

Another customer expectation that is directly affected by supply chain performance is time or responsiveness.

A product in high demand or consumed shortly after production would need to be inventoried or manufactured close to customers. Customers will migrate to better alternatives if supply chains are not designed to meet time requirements.

Supply chains that are not designed to meet time requirements will either be more expensive or fail.

Supply chains that are not designed to meet time requirements will either be more expensive or will fail as customers migrate to better alternatives. Please Click To Tweet

Supply Chain Priority 2 – Optimize Your Supply Chain Structure

Supply chain infrastructure decisions are frequently influenced by customer locations and expectations, partner locations, business goals, market, etc. Allowing one of these components to dictate structure without considering the entire supply chain will result in a suboptimal, rigid flow.

Customers’ locations and expectations are crucial starting points.

For example, suppose a customer requests that a product be delivered within four hours of placing an order. In that case, you must ensure that you have a process and location close enough to make and deliver the product within that time frame or that you have a location close enough to store product that you can deliver within four hours.

In this case, if your customer was in Europe and the product was manufactured in China, you would need to physically store products in Europe in locations that could meet the customer’s expectations within the 4-hour time frame.

Decisions on where to make a product, whether to keep inventory stores and where to store such inventory are all driven by customer locations and service expectations.

Partner locations are also important in this equation.

The nature of what partners supply and the characteristics of the products may dictate how much flexibility you have in where your product can be manufactured.

For many products and services, demand planning may be difficult or sometimes impossible. Therefore, the smart supply chain design must balance the opportunity to sell more products against the possibility of building capacity that is not used.

The ultimate goal of every supply chain manager is to produce and deliver a customer order within their time expectation (Just in Time) to avoid inventory and improve quality and freshness.

To meet those customer expectations, supply chain professionals must have the exact or even more stringent expectations of their supplier partners.

However, this is not always feasible due to the high cost of facilities. So, naturally, if the facility costs are extremely high, you will have to limit the number of production locations.

Although technological advances such as 3D printing and process miniaturization will change facility cost equations over time, there are still many constraints in place today.

So, for example, if you use a component that can only be supplied by a Japanese factory, this part of the global supply chain is considered immovable (fixed for some time). Further, suppose you manufacture the final product in Brazil, which requires the Japanese component. In that case, you will have to weigh the cost and reliability of getting shipments frequently from Japan against the costs of holding inventory in Brazil. But even with the most frequent shipments, you will end up holding some Japanese components in stock in Brazil.

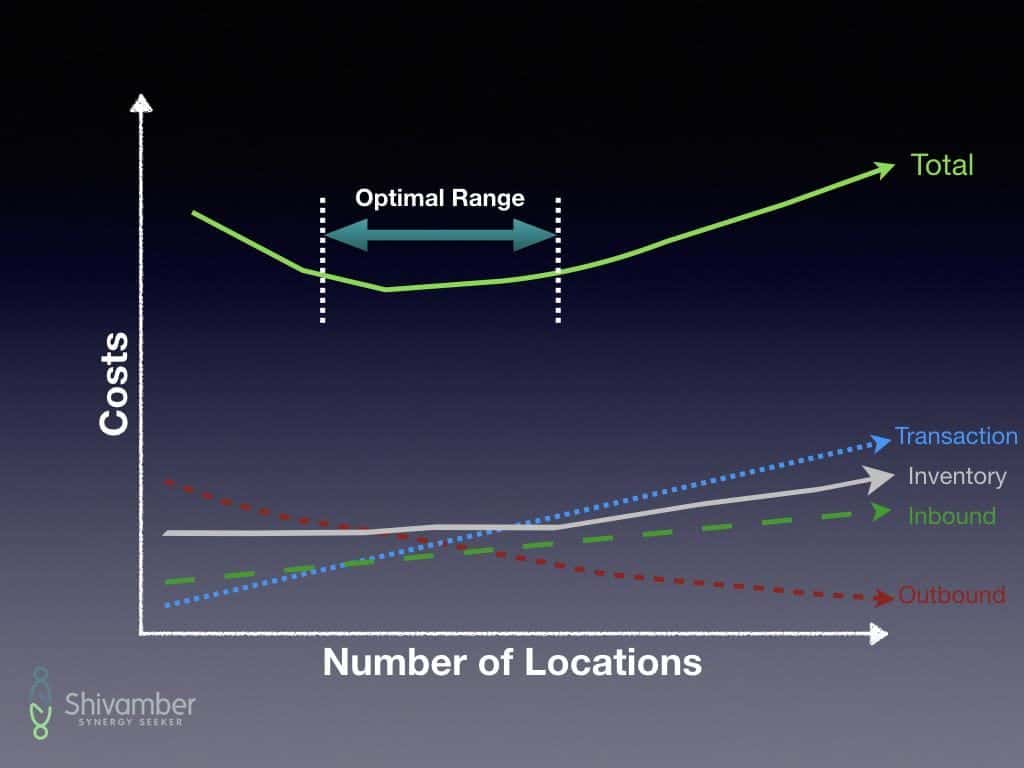

Traditional supply chain management systems frequently struggle in another area that is not so much related to the geography but due to the sheer number of locations/partners involved. In some cases, the impact of the number of sites may outweigh the effect of where decisions. For example, if you look at the diagram below, it is clear that having an excessive number of significant locations would significantly impact a supply chain.

So the supply chain structure, and specifically where and how many locations are required will dictate your ability to get products to customers quickly, at a reasonable cost.

The above chain would become more challenging to coordinate and manage as the number of locations and partners increased.

With the modern global market being as competitive as it is, even for small businesses, managers must strive to reduce labor and material costs in a progressive, flexible manner.

Many companies have outsourced parts of their manufacturing or supply chain activity to third-party partners. They can overcome the high facility cost in the equation or minimize the inherent complexity of multiple locations by sharing the capacity of these partners, sometimes even with competitors.

Managing the flow of information from various partners is an essential part of planning the structure of any supply chain, which directly impacts the chain’s performance.

When considering supply chain performance in terms of information, the following factors come into play: information quality, speed, and the resulting executive decisions. In addition, the supply chain planning information must be transferred between supply chain participants without losing its value to ensure desired product/service flow.

This supply chain visibility can be difficult when many people are on the job and have an outdated information system. Therefore, selecting and implementing an information system written to complement your specific supply chain would be beneficial.

The smarter supply chain requires sophisticated capabilities, including machine learning and advanced analytics, and an appropriate business process design should be linked. In addition, the system should allow for flexibility, collaborative supply chain planning, and data sharing among key players.

As the supply chain structure becomes more complex, supply chain visibility and supply chain management become a more complex beast. Increasing the number of locations, geographically dispersing across the globe, the Internet of Things (IoT), and more real-time accumulation of social media data and customer activity add up to a mountain of data never seen by managers before (Big Data). And managing these increasingly sophisticated data pools will necessitate significant investments in supply chain analytics to enable more effective supply chain management.

Supply Chain Priority 3 – Build Great Supply Chain Partnerships

When considering partnerships, keep your business and market priorities lean – there should be no ‘fat’ on either your business or your trading partners’ parts – each must be able to provide high-quality output in a cost-effective and timely manner independently.

No supply chain would be complete without several participants.

Consistent market leadership means that there is no room in the supply chain for ‘being precious’; no supply chain provider can provide all of the necessary products and services on their own.

Good supply chains will require multiple relationships to meet the needs of customers consistently.

Partner relationship management, like location management, can be tricky in terms of costs and added complexity. Unfortunately, it is common for businesses to select partners solely based on the price offered – this can have a significant negative impact on the overall performance of the supply chain in the long run.

The cost of doing business with any given supplier is not fully reflected in the price. In some cases, it may be preferable to increase expenditures in one segment of the chain to get better performance in another part of the chain and to achieve the desired result – Lower total cost for the entire chain.

Price doesn't fully reflect all of the costs associated with doing business Please Click To TweetHere are three critical points to consider when evaluating possible collaborations:

- The approach to partnership in your supply chain strategy should be based on the fundamentals of essential businessmanagement, such as time, quality, and service. In addition, take notes on the potential partner’s capabilities because, as the adage goes, a chain is only as strong as its weakest link.

- Adding new partners or replacing existing ones may necessitate significant changes to the business’s organizational structure. In addition, supply chain issues frequently cross both the business entity and functional ends of the company.

- Finally, depending on the number of trading partners involved and the complexity of the supply chain, you should implement appropriate information and measurement system to assess the overall performance of the supply chain. To ensure that all partners are simultaneously focused on maintaining a lean supply chain, defining meaningful, relevant, and achievable targets is critical.

A solid structure in place increases the likelihood of an effective supply chain operation, but it does not guarantee it.

Collaboration, like any other relationship, must be founded on trust, and it necessitates that all participants make individual sacrifices to achieve total improvement. Because these collaborations connect the entire chain, all improvements do not have to come from the company’s margins – all participants must demonstrate a willingness to go beyond traditional measures.

Some supply chains may need to go against traditional business practices to focus on the ultimate success of the product/service with its target audience.

With the complex decisions that supply chain managers face, it is often beneficial to seek the advice or experience of an entity that is not directly involved in your supply chain (if your adviser has a stake in one or more aspects of the supply chain, you can expect the solutions to lean towards their experience).

You’ll need to find an unbiased, talent-rich, and experienced organization to work with – choose wisely from the numerous supply chain consulting firms that have established themselves as supply chain guides in recent years.

The curious supply chain professional can learn much from the Amazon supply chain design or the Apple supply chain structure. Some of the best-performing global supply chains have gone through their supply chain transformation and broken away from the limits of legacy supply chain services.

Bringing in an outside team should mean you’ll get lots of experience, and a practical, counter-intuitive perspective on the overall chain’s vision.

What are the major Trends affecting the Supply Chain?

Every year, customers have higher expectations – they want more for less, or they’ll get it elsewhere. Perhaps your competitor is a small entrepreneur in China selling a high-quality version of your product from their garage.

For rigidly structured existing supply chains,’ more for less’ for customers often means that the supply chain must absorb higher costs. Thus, as a wise supply chain manager, you must prepare your chain for emerging market trends that will undoubtedly drive change.

Every year brings with it higher expectations from customers – they want more for less or they’ll simply get it elsewhere Please Click To TweetHere are a few key trends affecting the supply chain and supply chain management:

Globalization

Globalization creates numerous opportunities for both the demand and supply sectors, but it also adds a significant level of complexity to any supply chain. In supply chain terminology, more options imply a higher level of coordination and flexibility to ensure effective processes in diverse international markets.

Outsourcing

Introducing an outsourced partner could reduce supply chain costs while increasing communication and coordination challenges in the procurement and management processes, whether manufacturing, design, or another supply chain function.

Less Time to Market

This trend puts a lot of strain on the supply chain, especially since it’s a moving target that’s constantly being squeezed. The shorter the time it takes for a product or service to reach the market, the greater the competitive advantage and profit potential.

Mass Customization

By tailoring product bundles to individual customer needs, businesses can extract more profit for the value they provide to their customers while also increasing loyalty. While this is a win-win situation for both the brand and its customers, mass customization is difficult for traditional supply chains to handle.

Tailoring product bundles to individual customer needs have enabled companies to extract more profit for the value they provide to their customers, and simultaneously increase loyalty. Please Click To TweetPricing Pressure

Few industries have consistently raised prices in recent years; instead, many enterprises have provided more value to their customers while maintaining or lowering prices. This trend towards increasing value means that there will be more pressure to cut any excess in the supply chain. To deal with these pressures and capitalize on other emerging trends, enterprises must redesign most supply chains to cope with and fit the new marketplace priorities.

All these global trends collectively point to continuing supply chain disruption, and the corresponding need for supply chain leaders to be transforming their capabilities to meet the anticipated future requirements.

Conclusion

In conclusion, I will leave you with four burning questions that every supply chain manager should review and address regularly:

- First, can you clearly define your customers’ cost, quality, and time expectations?

- Is your supply chain set up to meet existing, or worse, past customer expectations, or is it ready to be a differentiated benchmark performer in the future?

- Are you confident in your partners’ abilities, and have you created an integrated ecosystem of partnerships that can provide a competitive advantage?

- Is your use of timely and high-quality information suitable for advanced supply chain analytics, and the necessary supply chain visibility required for driving constructive, collaborative planning and effective supply chain management?

Continuous revision of these responses will result in a lean, competitive supply chain with meaningful targets and the ultimate goal of retaining happy customers.

Frequently Asked Questions

What is a supply chain?

A supply chain is a network of organizations, people, activities, information, and resources involved in producing and delivering products or services to a customer. Natural resources, raw materials, and components are transformed into a finished product and delivered to the end customer as part of supply chain activities.

What is Supply Chain Management?

Supply chain management refers to the active management of supply chain-related activities (from design, procurement, through manufacturing, delivery, and after-sales service) to increase long-term competitive advantage and customer value at the same time.

What is the difference between supply chain and logistics?

The terms supply chain and logistics are sometimes used interchangeably as if they were the same thing. They are not. Logistics is an essential subset of the global supply chain and refers specifically to the part of the supply chain that deals with the planning, control, movement, and storage of goods and services.

What is the difference between supply chain and operations?

The terms supply chain and operations are sometimes described as discrete and completely different activities. They are not. Operations are an essential subset of the global supply chain and refer specifically to the part of the supply chain that is typically internal to the company making the product. The controversy is a function of the historical organizational separation of focus between manufacturing (what happens inside) and everything else (outside).

For some companies, manufacturing operations can be incredibly costly and represent the most significant portion of the total product costs. Therefore, these organizations typically manage their manufacturing operations as a critical focused asset. In those businesses, the supply chain responsibility is focused on the other, generally external activities. However, large segments of modern electronics are built in outsourced manufacturing facilities, and in contemporary organizations, supply chain functions will encompass manufacturing activities.

What is Supply Chain Resilience?

Supply chain resilience is “the capacity of a supply chain to persist, adapt, or transform in the face of change.” Persistence refers to the ability to bounce back as quickly as possible under stress to normal conditions. Adapting means finding workarounds to bottlenecks and limitations, while transformation is the fundamental redesign to escape historical constraints and produce new capabilities.

What Is a Sustainable Supply Chain?

The term “supply chain sustainability” refers to companies’ efforts to consider their products’ environmental and human impact through the supply chain. A sustainable supply chain delivers products in a socially conscious and balanced way without contributing to environmental harm. The goal is to reduce the ecological damage caused by factors such as energy consumption, water consumption, and waste generation while also positively impacting the people and communities in and around their operations.

What Is Sustainable Supply Chain Management?

While traditional supply chain management focuses on operational speed, cost, and reliability, sustainable supply chain management incorporates the broader goals of social and environmental principles. This expanded mandate includes dealing with global challenges such as corruption, diversity and human rights, deforestation, fair labor practices, and protecting the environment, among others.

What is a digital supply chain?

A digital supply chain is a collaborative network that uses information technology to improve the efficiency and effectiveness of supply chains. As with all digital transformations, the conventional wisdom will tell you that it takes five to ten years and lots of money to modernize a corporation’s supply chain. However, experience shows that a well-managed supply chain transformation is completed much more rapidly and at a much lower cost.

Helpful Materials

Professional Supply Chain Organizations

- American Society of Transportation and Logistics (AST&L) [Merged with APICS below]

- Association for Supply Chain Management (ASCM)

- Chartered Institute of Procurement & Supply (CIPS)

- Chartered Institute of Supply Chain Management (CISCM)

- Institute of Supply Chain Management (IoSCM)

- Institute for Supply Management (ISM)

- International Institute for Procurement and Market Research (IIPMR)

- International Supply Chain Education Alliance (ISCEA)

- The Association for Operations Management (APICS) [Now rebranded as ASCM above]

Supply Chain Professional Certifications

- Certification in Transportation and Logistics (CTL)

- Certified Demand Driven Planner (CDDP)

- Certified International Supply Chain Manager (CISCM)

- Certified Procurement Professional (CPP)

- Certified Production and Inventory Management (CPIM)

- Certified Professional in Supply Management (CPSM)

- Certified Purchasing Manager (CPM)

- Certified Supply Chain Analyst (CSCA)

- Chartered Supply Chain Management Professional (CSCMP)

- Certified Supply Chain Manager (CSCM)

- Certified Supply Chain Professional (CSCP)

- Certified Supply Chain Specialist (CSCS)

- Supply Chain Management Professional (SCMP)